Real-globe practice is essential to passing examinations and turning out to be self-confident inside your testing capabilities. Numerous NDT job guides recommend logging hours below a Accredited Expert. UTI’s schooling emphasizes authentic-world application.

Visual screening remains the preferred NDT method across all industries. It requires taking a thorough look at the specimen and obtaining defects which are noticeable to the bare eye.

Papers for the Investigation and Evaluation Journal of Nondestructive Tests (ReJNDT) needs to be submitted with reference to particular calls from NDT.Internet or in reference to pertinent conferences phone calls. With regards to the evaluation approach, particular submission data might be offered with the decision.

Situation Checking: Assesses the issue of in-company pieces and buildings, supporting predict servicing wants and increase service life.

1924 – Lester makes use of radiography to examine castings being put in inside of a Boston Edison Company steam force energy plant.

“What a great area to know from gurus in our marketplace, not only in your region, but throughout the world. I really recognize the valuable dialouge that happens on ndt.Web and being an exhibitor, we get pleasure from the mediumr, worldwide viewers.”

This sort of tests will allow steady inspection and checking without the need of sacrificing the integrity of the object being tested—rendering it ideal for safety-important industries.

The reaction or proof from an assessment, for instance a blip on the screen of the instrument. Indications are categorized as true or Untrue. Fake indications are All those caused by factors not related to the principles of the screening method or by inappropriate implementation of the strategy, like film harm in radiography, electrical interference in ultrasonic screening etc.

NDT is integral to quality Handle processes, making certain solutions meet stringent industry specifications and requirements, by making use of techniques like ultrasonic and radiographic screening to detect inner and floor defects.

Perfect for inspecting ferromagnetic elements which is a normal Component of lots of NDT certification exams.

Non-Harmful Testing (NDT) is made up of approaches Utilized in science and industry to investigate resources, components, or units devoid of leading to them any damage. The key element of NDT is it allows us to evaluate the Homes of materials, parts, or techniques without resulting in any destruction, meaning the tested goods can nevertheless be utilised after the inspection, preserving the two time and resources.

Level II: Competent to arrange and calibrate products, interpret and Assess final results, and organize and report findings, also able of training and guiding Stage I personnel.

Degree 1 are specialists experienced to complete only distinct calibrations and assessments underneath close supervision and direction by better amount staff. They can only report test results. Non-destructive Testing (NDT) Training Normally they work subsequent particular function Directions for testing methods and rejection requirements.

It's really a quick and possible means of monitoring product quality at every single stage in the production procedure along with for all those products that are in service.

Ralph Macchio Then & Now!

Ralph Macchio Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Bo Derek Then & Now!

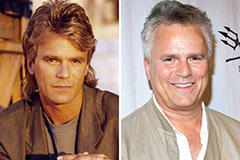

Bo Derek Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!